The MT72xx family combines high EMC resilience and functional safety with a two-wire interface.

Novosense recently introduced the MT72xx series of two-wire Hall-effect switches for improved signal integrity and reliability in long-wiring automotive applications.

The packaging options for the MT72xx family. Image (modified) used courtesy of Novosense

The release comes at a time when wiring harnesses are growing longer and more complex, leading to signal degradation and installation costs as prominent issues. Novosense's MT72xx series attempts to resolve these problems with a two-wire output interface and integrated protection circuitry.

The New Hall-Effect ICs Tackle Automotive Long-Wiring

The MT72xx ICs address space constraints in automotive applications, employing a two-wire current output configuration that reduces connector and harness complexity compared to traditional open-drain output designs.

The chip is also highly integrated to save overall PCB area. Built using Bipolar-CMOS-DMOS (BCD) process technology, these ICs incorporate an on-chip Hall voltage generator, voltage regulator, temperature compensation, a small-signal amplifier, dynamic offset cancellation, and a Schmitt trigger within a single die.

Functionally, the MT72xx series supports an operating voltage range from 2.8 V to 26 V and integrates a 100-nF capacitor (in the TO-92S variant) to improve ESD and EMC performance. This built-in filtering promises stable operation under high electromagnetic interference. Other features include integrated -30-V reverse power protection, reverse current clamping, and support for 12-kV HBM ESD performance. In terms of packaging, users can choose between surface-mount SOT-23 and SOT-23 (thin) or through-hole flat TO-92, all RoHS compliant.

Functional versatility is another design focus of the MT72xx line. It offers unipolar, omnipolar, and latch-type magnetic sensing with configurable sensitivity thresholds to accommodate varied magnet arrangements and detection requirements.

Understanding BCD Technology

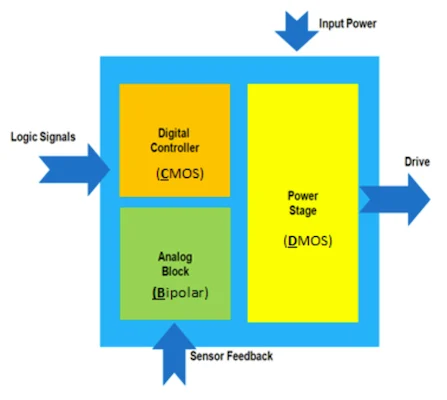

One of the defining features of the MT72xx series is its fabrication using Bipolar-CMOS-DMOS (BCD) process technology. This method combines bipolar transistors for analog precision, CMOS for digital logic, and DMOS for high-voltage power control together on a single monolithic die.

From a system integration perspective, BCD drastically reduces board space and bill-of-materials (BoM) complexity. Designers can co-locate logic, signal conditioning, and high-voltage drivers without needing separate ICs. This effectively minimizes parasitics, reduces assembly costs, and improves reliability in high-density automotive systems.

BCD process. Image used courtesy of Arm

Foundries favor BCD for its economic efficiency because it allows the reuse of mature 200-mm fabrication equipment while supporting technology nodes down to 130 nm. For power management ICs in mobile and industrial systems, 180 nm often strikes a balance between density and cost. BCD extends into applications like motor control, where its integration with 32-bit MCUs enables advanced algorithms in automotive actuators and hard disk drives.

A Platform for Scalable Sensor Design

As domain controllers expand and body electronics become increasingly modular, engineers need more high-integration, robust components. By leveraging BCD integration and a two-wire interface, Novosense claims its new Hall switches will provide a solution for sensor nodes with reduced wiring and system complexity.

To support developers, Novosense is offering demo boards and magnetic field simulation tools for accelerating validation and debugging. The devices are currently available in multiple package formats through authorized distributors.

-

Tel

+86 180 2549 2789 -

Wechat

BOM

BOM Cart()

Cart() English

English Russia

Russia Korean

Korean